HVAC Training Institute

HVAC Execution

- 45 Days Training

- Project Work With Next Trends

- Placement Assistance.

HVAC Execution course helps you to execute design on site by going through the pictorial representation of design.

The Course enables the entry level and working engineers to understand the basics, different systems used in Air Conditioning for Domestic and commercial purposes.

To achieve the execution, one should needs good analytical skills and up-to-date technical knowledge of various systems in site. This training is useful to execute the HVAC Systems by managing the all the site departments in smooth manner with out any hindrance of the site other services like plumbing and Electrical. This training is an opportunity to apply the academics and develop an understanding of how to develop solution-driven concepts and translate them into a complete set of plans and prototypes.

HVAC Required in Commercial Buildings, Airports, Shopping malls, Petrochemical complex, refineries, pharmaceutical industry, Aerospace industry, Hospitals etc..,

1. Basics & Fundamentals

2. Basic Components and Classification of Components

3. Categorization of Air Conditioning System.

4. Basic HVAC Terminology

5. Study of Drawing

a.Legends and Symbols

b. Observations

c. Understanding with Clarity about to site conditions

d. Remembrances.

6. Clearances

a. Site Clearances for ducting, piping and other works.

b. Installation of Equipments etc.,

c. Civil Clearances.

7. Planning and Co-ordination

a. Coordination with

i. Client and Consultant.

ii. Civil Engineers

iii. Electrical Engineers

iv. Plumbing engineers

v. Fire Protection Etc...

8. Material Management/Store Management

a. Material indent.

b. Proper usage of material.

i. Limited material usage/ no wastage of material

(Ex: - site fabrication of GI sheets, aluminum claddingSheets, Insulation material, and Piping etc)

ii. Material security.

iii. No shortage of material.

iv. Requirement of material.

v. Proper planning of material usage and availability of material.

vi. Not to cross the PO cost.

c. Excesses material return back to the store.

6. Labor Management

a. Maintain the manpower planning.

Various types of man power

i. Ducting contractor.

ii. Piping contractor.

iii. Insulation contractor.

iv.AHU/CT/Chiller/Technicians/Assembler

v. Material shifting contractor.

7. Simultaneously follow of various departments

8. Reviews, strategy of planning work, billings etc.

9. Testing & commissioning.

Air side

a. Mechanical equipments start up.

b. Floor side air balancing.

c. Toilet EA balancing.

d. Rotation of blowers.

e. DB levels checking.

f. AHU RA, FA Quantity, Temperature and Pressure levels checking. Etc

g. Documentation of TC protocols.

Water side

a) Fleshing of water in pipe line.

b) Water balancing.

c) Pressure balancing.

d) Identification and Arresting Leaks in water System.

e) Documentation of TC protocols.

10. Handing over of the project.

As built drawings submission.

Proper commissioning reports.

Test certificates.

Operation manuals.

Escalation chart for the services.

11. Returning of the excess material to the stores dept.

12. Closing of the end of the final bill.

List of HVAC Equipment Installations

1. High Side Installations.

a. Chillers

b. Pumps

c. Cooling Towers

d. AHUs

e. Pipe Line Work /layouts

f. VRF/VRV System Installation

2. Low Side Installation

a. All Air System

b. AHU to w/s Ducting

c. SA Ducting

d. RA Ducting

e. FA Ducting

f. Fitting used for Ducting Network. (VCD, FD, PAFD, MVCD, VAV, Grills, Diffusers Etc…)

g. Toilet Exhaust Ducting

h. Toilet - M/Cs, fittings and accessories.

i. Domestic Units Installation

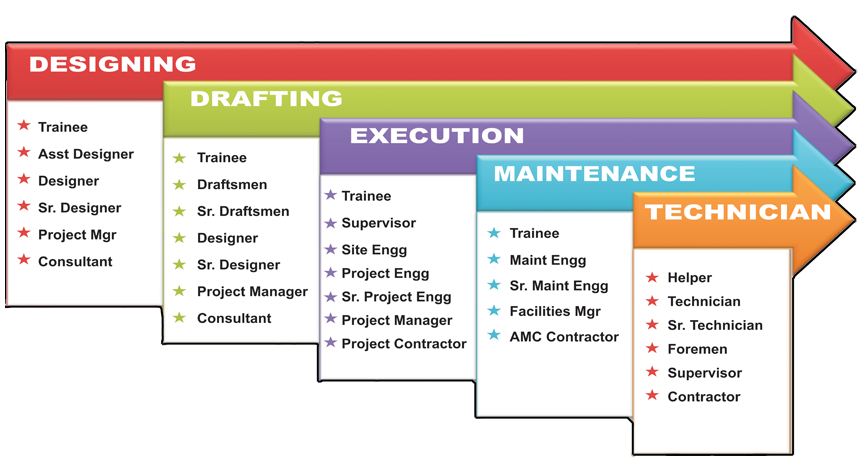

21st century demands conditioned air every where.Heating, ventilation and air conditioning requires precise engineering with a proper plan set by the company’s respective project team. An HVAC system requires a strong combination of mechanical and electrical applications. Now companies that incorporate HVAC projects are also a part of MEP projects-mechanical, electrical and plumbing. Hence the best course for you that can fetch you a job in either of the projects.